10mm~2000mm and 1/2 "~80"

Working pressure:

0.25MPa~76.0MPa/150Lb~4500Lb

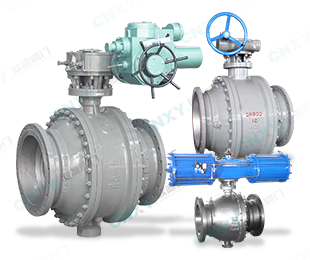

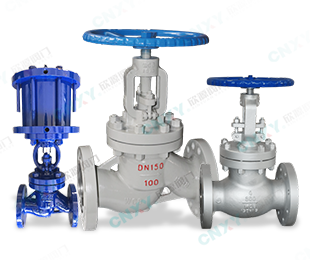

The main products of the enterprise include more than 10 categories, including butterfly valves, gate valves, globe valves, ball valves, check valves, filters, pneumatic and electric valves, and fluid equipment, with a total of over 1000 models and specifications.

Quality Control

Every product undergoes strict monitoring,

The QC department will strictly control and record every detail.

Competitive Prices

Provide products of expected quality at competitive prices,

Winning the recognition of numerous customers

Fast Logistics

Mature shipping process, good logistics partners,

Ensure that customers receive the products they need in the shortest possible time.

7 * 24-hour service

There is an excellent after-sales service team,

Ensure timely resolution of customer after-sales issues.

The product is widely used in power plants, petroleum, chemical, pharmaceutical, gas, food, paper, water supply and drainage, air conditioning, pipeline systems and other fields. Welcome friends from all walks of life to visit, guide and negotiate business.

Welcome knowledgeable people from home and abroad to visit our company for inspection and cooperation. We are willing to work together with friends from all walks of life to create brilliance!